The World’s Garbage Can: On the Human Consequences of Mass Export of Waste

Oliver Franklin-Wallis Explores the Outsourcing of Trash

The stories began in early 2018. Always different, always the same. There would be a village, a town. Then, suddenly, plastic factories would arrive. Small operations: shredders, extruders. Nurdle factories. Men would appear, advertising work, profit to be made. Then: smoke. The smell of burning polymers in the night. Locals reporting headaches, breathing problems. In one case, children started to develop skin rashes. Dumps accruing in the fields, in waterways, in ditches, the labels invariably in foreign tongues.

Perak, Malaysia: Heinz beans wrappers, Flora margarine tub. Yeo Valley yogurt pot. Listerine mouthwash. Recycling bags from four London councils. Cat food pouches from Spain. Wafer packets from Germany. Factory offcuts from Australia. US postal service boxes. Fiji water bottles, Made in USA.

East Java, Indonesia: Gatorade bottle. Arizona Sweet Tea. Capri Sun packets from the UK. Dish soap from Finland. Whiskas cat food, Hershey’s cookies. Even the occasional banknote, slipped accidentally into the trash: US dollars, Canadian dollars, Russian rubles, Saudi riyals, Korean won.

Adana, Turkey: Andrex toilet roll wrappers. KP salted peanuts packet, Asda cashews. Marks & Spencer bacon. McCain’s home fries. Cherry Pepsi Max. A Tesco plastic bag, emblazoned with flowers, and the phrase “REUSE AT HOME, RECYCLE. Every little helps.”

What do you do if you’re the waste industry, collecting thousands of tons of mixed, contaminated, or multilayered plastics that—largely unknown to the general public—are impossible or unprofitable to recycle? You make it somebody else’s problem.

Exporting waste is nothing new. Wastepaper, rags, and scrap metals have been traded for centuries. In Victorian London, for example, one “volcano-like” dust heap that towered over King’s Cross in 1826 was shipped to Russia to be used in the rebuilding of Moscow after the devastating fire of 1812. Waste was and is material—like any commodity, it moves where the market is. But the global waste trade in its current form did not truly take off until the second half of the twentieth century, as consumers in the Global North began gorging on cheap goods made largely in Asia.

By the 1990s, the act of making things had largely been exported—that is to say, globalized, chasing cheap labor. But, while thousands of shipping containers arrived in the West every day from Chinese ports packed to the brim with our every need (and plenty of things we didn’t know we needed yet), there was little to send back. China buys far less from the West than it sells (the so-called “trade deficit”). Rather than sail back empty, canny entrepreneurs began to fill the containers with our most abundant product: waste.

At first, these exports were predominantly scrap metal, which was desperately needed by the exploding Chinese manufacturing industry. As the journalist Adam Minter writes in his scrap travelogue Junkyard Planet, although the US in particular was still producing prodigious quantities of excess metal, many American smelters were closing due to tightening environmental standards, a problem they didn’t face in China.

Chinese waste imports continued to grow, and when the country was finally admitted to the World Trade Organization in 2000, a metaphorical dam broke. The flow became a torrent. Between 2003 and 2011, China’s scrap imports increased sevenfold. The country was soon the leading destination worldwide for waste steel, copper, aluminum, paper—and eventually, plastics. By 2016, the United States alone was sending 1,500 shipping containers full of waste to China every day.

By 2011, Wen’an’s Xiaobai river was so toxic that when used to irrigate farmland, it wiped out the crops. Locals told of lung problems and of men so sick that they failed military entrance exams.

It’s hard to fully measure the extent to which China’s economic miracle was enabled by Western waste. For China, the benefits of importing our garbage were clear: its industry needed raw materials, and there was not enough domestic supply to fill the world’s ravenous appetite for Made in China goods. It was also, in some ways, more sustainable.

By recycling the West’s waste instead of using virgin equivalent, China prevented the emissions of untold millions of metric tons of CO₂, and the extraction of billions of tons of ore. Trash flooded into regions like Guangdong, “the Scrapyard to the World,” as Minter describes it, “a place where wealthy countries sent the stuff that they couldn’t or wouldn’t recycle themselves; a place where former farmers took that stuff, made it into new stuff, and resold it to the same countries that had exported it in the first place.” Countless polan wang, or “junk kings,” got rich off this new industry, among them Zhang Yin of the paper recycling giant Nine Dragons, who became China’s first female billionaire.

Everything had a market: plastics and scrap electronics could be sold to Chenghai, the so called “Toy City,” where millions of plastic playthings are made, often from allegedly toxic materials; or Yiwu, nicknamed “Christmas village” for turning out more than 60 percent of the world’s festive tchotchkes. In the south, a thriving electronics recycling industry imported millions of metric tons of discarded electronics in what was known as chengshi kuanchan, or “urban mining”—wreaking pollution and, over time, helping to transform China into an electronics manufacturing powerhouse.

The scale of Chinese recycling by the early 2000s is hard to even picture. In Wen’an, a formerly rural region south of Beijing, as many as 20,000 plastics processors—and an estimated 100,000 workers—set up shop in just a handful of villages, sorting, shredding, and melting plastic down to feed the country’s voracious manufacturing base. These recyclers lacked even basic safety equipment or environmental controls. Polluted wastewater filled the nearby streams, killing off the fish; the pollution was so severe that locals started to drink only bottled water.

By 2011, Wen’an’s Xiaobai river was so toxic that when used to irrigate farmland, it wiped out the crops. Locals told of lung problems and of men so sick that they failed military entrance exams. The problem was not just associated with plastics. In Guiyu, where scrapped electronics were recycled, the ground and water was blighted with heavy metals, dioxins, and polychlorinated biphenyls. According to one study, a quarter of newborns in Guiyu had elevated levels of cadmium in their bloodstreams, which can lead to cancer, osteoporosis, and kidney damage, among other harmful effects. In another, 81 percent of children tested suffered from lead poisoning.

Crackdowns have since cleared much of the informal recycling in We’nan and other areas of China, and concentrated it into more tightly regulated “economic zones.” But similar conditions have been reported wherever informal recycling takes hold. I have seen it myself.

______________________________________

Excerpted from WASTELAND: The Secret World of Waste and the Urgent Search for a Cleaner Future by Oliver Franklin-Wallis. Copyright © 2023. Available from Hachette Books, an imprint of Hachette Book Group, Inc.

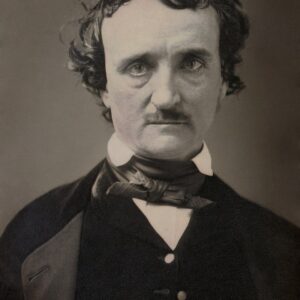

Oliver Franklin-Wallis

Oliver Franklin-Wallis is an award-winning magazine journalist and currently the features editor of British GQ. His writing has appeared in GQ, WIRED, The Guardian, The New York Times, The Economist, The Times Magazine, The Sunday Times Magazine, Men’s Health, and many other publications. In 2017, he was named “Print Writer of the Year” by the British Society of Magazine Editors. He has spoken at events such as WIRED Live, Web Summit, and London Tech Week. He has appeared on TV, radio and podcasts, including the WIRED podcast, BBC Radio 4, Radio 5 Live, and BBC World Service. He lives in Hertfordshire with his wife and daughter.