On the Beauty and Art of Making a Watch

“One of the key skills for any watchmaker is the ability to find tiny shiny things on the floor.”

When I first started training as a watchmaker at nineteen, I was taught never to leave a trace of my presence within the watches I restored. And yet, these traces can tell us all kinds of stories about otherwise inanimate objects. For example, the vintage Omega Seamaster wristwatch on my workbench was repaired by a man called Jeff on 10 March 1971. I know this because Jeff scratched his name and the service date into the back of the dial, so that if the watch ever came back to him, he would know that he had previously worked on it and when.

Working as we do on objects only a few centimeters in diameter, a watchmaker’s world is often not much bigger than a thumbnail. It is all-consuming. Sometimes a whole morning passes and I have barely shifted my gaze beyond the postage-stamp-sized mechanism I am working on. I suddenly realize the coffee next to me is cold and my eyes are dry from concentrating so hard I’ve forgotten to blink.

My husband, Craig, is also a watchmaker and, although we work on benches that face each other, we can spend whole days in near silence, exchanging little conversation beyond orders for the kettle. When we make a new watch, whether from salvaged parts or from scratch, it can take us anywhere from six months to six years. We can measure sections of our lives by these watches, and sometimes find ourselves noticeably older when we are finished with them.

Our workshop is in an eighteenth-century goldsmiths’ factory in Birmingham’s historic Jewelery Quarter. Craftspeople have been producing work here for seven generations and the walls feel steeped in appropriate history. The rooms beneath us contain centuries-old presses, dies and design charts, as well as artisans still using this equipment to produce jewelery. Our small room on the top floor is bright and airy, with skylights and arched windows.

When we first moved in and were preparing the space, we were told that during the Blitz a bomb had crashed through the roof and failed to detonate. I pulled down an old insulation screen covering the skylight and found a beam still charred from the blast, which I scrubbed and left on show. It now presides over our lathe bench and wheel-cutting machine, which, ironically, is German. We call her Helga. She sits on a long bench that extends down the whole side of our workshop and is covered with a variety of old machines.

Underneath, there are copious drawers full of the dull gleam of old watch mechanisms and parts that we have sourced or rescued over the years—often from bullion traders who had taken them out of their cases, which were to be sold as scrap gold or silver, or from the workshops of watchmakers past being cleared out by their families. Our ‘clean’ watchmaking benches are on the opposite side of the workshop, as far as possible from the swarf (metal shavings) and oil that occasionally spit from the machines.

We keep our workshop very clean, to avoid dust or dirt finding its way into the delicate watch mechanisms. In the state-of-the-art watch manufactories of Switzerland or East Asia, workshops will have double air-lock doors and sticky mats to remove dirt from shoes, and watchmakers wear compulsory lab coats and shower caps over their feet. We are a little more relaxed. Our dog, Archie, snoozes in a corner.

By the end of a day making new watch parts the room smells of lathe oil, a distinctive aroma almost like that of a tomato vine, with notes of metallic copper and iron. There will be small mounds of brass or steel swarf scattered around our lathes, mills and drills, as well as oil-and coffee-ring-stained sketches of parts strewn liberally across the workbenches.

We sweep the floor regularly, ready for the occasional team hunt for accidentally flicked parts—you could probably make up a complete watch from the parts stuck between floorboards or rolling under sets of drawers in most watchmaking workshops. Our floor is pale grey vinyl, the perfect contrast for the yellow of brass or bright red of a ruby jewel. No one tells you that one of the key skills for any watchmaker is the ability to find tiny shiny things on the floor.

The last residents of our workshop were enamelers, and traditional makers have worked in this space for over two centuries. In this room at least, not much has changed. Although we have modern computers, most of the tools and machines we work with are between 50 and 150 years old. Our skills too, are from a bygone era.

In the “golden age” of watchmaking that ran through the seventeenth and eighteenth centuries, Britain was the centre of the watchmaking world. Now watchmakers like Craig and me are a rare breed. In 2012 we set up on our own, becoming just one of a handful of firms in the UK with the skills to make mechanical watches from scratch and to restore antique watches from the last five centuries. But the course we trained on no longer exists. The Heritage Crafts Red List of Endangered Crafts (much like the Red List of Threatened Species but for craft) currently lists artisanal watchmaking as a critically endangered skill in the UK.

In part our skillset is disappearing because, in our technologically advanced age, computer numerical control (CNC) can virtually make a whole watch for you. And you might well ask why we bother with this old equipment when we could feed a computer design into a software-operated machine to do most of the manufacturing for us instead. But where’s the fun in that? We love getting our hands dirty making things and fiddling with little parts to get them to work together.

As time went on, it felt very natural to me to begin switching between working on watches and thinking and writing about them and their history.

You build a closer relationship with what you’re making when you work by hand. You can hear when the cutting speed of a lathe or drill is perfect, and you can feel from the resistance whether the pressure of your tool is correct. We like this sense of connection to the objects, and to the generations of artisans who came before us.

*

I have always been fascinated by time, but I never set out to be a watchmaker. At school I wanted to be a pathologist (this was long before TV crime dramas made forensics cool). I was an oddball who was fascinated by how things worked, particularly bodies. I wanted to help people, but I wasn’t always very good at actually talking to them; working with the dead, I reasoned, would save me a lot of difficult conversations with patients. I liked the idea of figuring out why a body had stopped functioning. In the process I hoped I might help other people, perhaps by helping to bring about justice, or a deeper understanding of a deadly disease.

My career as a pathologist was never to be, but there is something forensic about working on old watches. Watch mechanisms contain tens if not hundreds, and occasionally thousands, of components, each of which has a specific task to perform. The most basic simply tell the time. The most complicated (the added functions in a watch that go beyond time-telling are in fact called “complications”) can chime the hours and minutes on gongs made from finely tuned wire, accurately maintain the date for over a century, or chart the stars.

When any of these parts become faulty or need cleaning, or re-oiling, they stop the mechanism from functioning. As restorers we dissect to determine the cause of death, only with the bonus that, once repaired and reassembled, our subject has another chance at life. The final stage of reassembling a mechanical watch is to replace the balance, which makes the watch start to tick again. There is nothing quite like hearing life restored to a piece that has not worked for years, or even centuries, knowing that its tick sounds the same to me now as it did to the watchmaker who first assembled it. The pulse of the balance is referred to as its “beat,” and the coiled spring used to regulate its action “breathes.”

As time went on, it felt very natural to me to begin switching between working on watches and thinking and writing about them and their history. I became the first practicing watchmaker in the UK to pursue a doctorate in antiquarian horology (the study of the history of timekeeping). After all, restorers are, in part, historians. It’s a practical kind of history: you have to know how something was made and how it once operated to return it to the way its maker intended.

Now I found it worked the other way too: when Craig and I first started making our own watches from scratch, my historical research and writing influenced the watches we made, in a sort of horological cross-fertilization. My research enlarged my tiny watchmaker’s world. The focus of the watchmaker is often smaller than a grain of rice, but the inspiration for horology is the universe—I love this contrast of micro and macro. And poring over the construction of an eighteenth-century watch to discern what it could tell me about its provenance and owners made me keenly aware not only of how history had shaped the watch, but also of how the watch has shaped us.

It would not be a stretch to say that the invention of mechanical timekeepers has been as significant for human culture as the printing press. Imagine trying to catch a train by relying on the position of the sun. Or organizing a Zoom conference of 200 people located all around the world, each trying to decipher the start time by hanging out of their window to be within earshot of the bells of the nearest public clock.

Or, at the more life-and-death end of the scale, think of surgeons performing an organ transplant or removing a tumor with no accurate reference point to measure their patient’s heart rate. Our ability to do business, structure our day, and access life-saving developments in science and medicine all rely on—are, in fact, made possible by—access to accurate time.

What we call a watch—a tiny, wearable clock—is a miracle of engineering.

From its very beginning the watch both reflected and developed our relationship with time. Watches don’t create time, they measure our cultural perception of time. All time-measuring devices, whether they are ancient carved bones or the watches I restore on my workbench, are a way of counting, measuring, analyzing the world around us.

The earliest timekeepers began by tracking naturally occurring phenomena in the world and solar system. Even now, the most up-to-date modeling devices we possess—smartwatches such as the Apple Watch—can still track a celestial routine, keeping pace with our planet as it hurtles round the sun over the course of a day. The systems we’ve developed to understand these processes, and our place within them, are our way of getting to grips with our universe, of applying a cosmic rational order that we can use to better live our lives.

What we call a watch—a tiny, wearable clock—is a miracle of engineering. Mechanical watches are among the most efficient machines ever created. I have worked on watches that haven’t been serviced since the 1980s, and yet have only just stopped running. I struggle to name another mechanism that would work day and night for nearly forty years before requiring any maintenance from a mechanic.

As of 2020, the most complicated watch in the world contains nearly 3,000 parts and is capable of measuring the Gregorian, Hebrew, astronomical and lunar calendars, chiming the hours and minutes together with fifty other complications, all in a device that fits in the palm of your hand. The smallest watch movement ever created was first made in the 1920s and fits ninety-eight parts into a volume of only 0.2 cubic centimeters. The first chronometer, a watch so accurate it could be used by sailors to calculate longitude at sea, was made over sixty years before the invention of the electric motor and over a hundred years before the first electric lighting. Watches have since accompanied humans to the summit of Everest, the depths of the Mariana Trench, both the North and the South Poles, and even to the moon.

Our concept of time is inseparable from our culture. In fact, the word time is the most commonly used noun in the English language. In Western, capitalist cultures time is something we have, or don’t have, save or lose, it marches on, it drags, seems to stand still and flies. Time thrums constantly underneath everything we do. It is the backdrop and the context for our existence and our place in what is now a supremely mechanized world.

_______________________

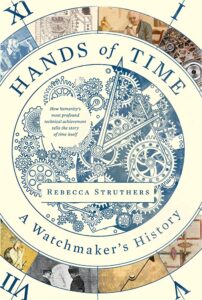

Excerpted from Hands of Time: A Watchmaker’s History by Rebecca Struthers. Used with permission of the publisher, Harper. Copyright 2023 by Rebecca Struthers.

Rebecca Struthers

Rebecca Struthers is a watchmaker and historian from Birmingham, England. She cofounded her workshop, Struthers Watchmakers, in 2012, with her husband, Craig. Together they use heritage equipment and traditional artisan techniques to restore antiquarian pieces and craft bespoke watches. In 2017 Rebecca became the first watchmaker in British history to earn a PhD in horology. Rebecca is one of the few remaining horologists in the world making timepieces from scratch. She lives in Staffordshire with Craig; her dog, Archie; cats Isla and Alabama; and Morrissey the mouse.