A Day in the Life of a West Virginia Coal Miner

Cave-ins, explosions, and hard, brutal work

The following is from James Green’s The Devil is Here in These Hills. Tomorrow night at 9pm PBS’s American Experience will broadcast The Mine Wars, based on the book.

West Virginia’s drift mines were cut into the mountains horizontally and its slope mines descended gradually into the earth. All of these mines included a main entry, or portal, and a second tunnel, or “monkey drift,” which provided workers with “ventilation”—a barely adequate suction through a surface grate created by a coal fire that burned all day. “Smoke from explosions of black powder, the reek of oil lamps, and the pervading coal dust made breathable air something of an obsession with the miner,” one miner recalled. A trapper like Frank had to pay close attention to his duties, opening and closing the doors regularly to keep the air moving and to allow coal cars to pass back and forth. He also learned not to scare the miners’ beloved pigeons or to be afraid of mine rats, because these creatures could sense danger coming before it struck.

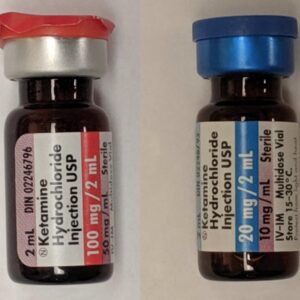

A mining company town in West Virginia.

A mining company town in West Virginia.

One threat the animals and birds could detect was the odor of gas that oozed from the ancient vegetation compacted over the ages. These deposits could produce “firedamp,” which contained methane and sometimes carbon dioxide that seeped out of the coal seams. Firedamp, described as “the monster most dreaded by the practical miner,” could explode if ignited by sparks or powder blasts, which would send fires raging through mine shafts with hurricane force.

Frank Keeney left no account of how he felt the day he entered the mine portal, but one imagines the dread that might have accompanied a ten-year-old boy’s first trip into the hole. For hours on end, a trapper boy’s ears would take in the strange sounds made by creaking timbers, rattling coal cars, clopping mules, and thudding blasts of explosions deep in the mine, while his eyes would behold surreal sights, like the white bones of ancient fish skeletons and the remains of tropical plants when they were illuminated by the miners’ lamps. Three decades earlier a boy about the same age—a newly emancipated slave—had worked in the same minefield. It was a dreadful experience Booker T. Washington never forgot. He later recalled his terror at being lost in a maze of underground rooms when his lamp went out. Without a match he walked, hands held in front of his body, until, by chance, someone found him and gave him a light. Fearful of the danger, frightened by the “blackest darkness” he could imagine, and repelled by the coal dust that clung to him like a layer of skin, Washington vowed to get an education and rise out of the coal pits, just as he had risen “up from slavery.”

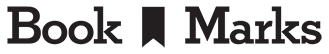

A West Virginia trapper boy.

A West Virginia trapper boy.

Most trapper boys learned how to overcome their fears by watching and listening to the colliers who went underground with them. When young Frank Keeney walked through a mine portal in 1892, perhaps an older miner, maybe a neighbor, offered him some words of consolation or, at least, instruction as they traveled in and out of the mine on what was known as a “man trip.” Or he might have heard some words of warning from the older boys who led the mules and coal cars back and forth through the door he tended. At suppertime, youngsters like Frank would sit with the men on a pile of slate and listen as veterans of the mine would sing songs, spin yarns, and tell jokes; they would rib the boys, trick them for laughs, and tell them tall tales of the devilish apparitions that appeared to them down in the hole. The veteran miners, who prided themselves on their toughness, taught the youngest ones how to act like men, how to ignore the pain, and how to laugh away their fears. Boys discovered that serious men turned into jokers when they toiled underground. Acquiring a sense of humor helped mask a worker’s dread of the mine, but joking was no substitute for learning how to be careful. In the words of the popular song “Miner’s Lifeguard,” written by a miner from Oak Hill, West Virginia:

A miner’s life is like a sailor’s,

’Board a ship to cross the wave;

Every day his life’s in danger,

Still he ventures to be brave.

Watch the rocks, they’re falling daily,

Careless miners always fail.

Mule drivers and trapper boys like Frank Keeney set out at six o’clock every morning with the adult miners, who each carried a pick and auger, a can of black blasting powder, fuses, and a tamping rod. The miners dressed in overalls, or “bank clothes,” for working the coal banks and wore cloth caps fitted with small oil lamps that lit their way in the tunnels. At dawn, the workers reported to the payroll clerk in the company office, where they were handed numbered brass checks to attach to each coal car they loaded. After checking in, they climbed up a steep trail from the office to the portal of a mine. Then, with their lamps casting a dim yellow light on the dark hillside, the men and boys disappeared one by one into the hole, like ants entering a colony.

Every workday a “panel” of miners, ranging from fourteen to twenty-eight men, passed through a main entry and then turned down a side entry. Every three or four hundred feet, passageways were cut, creating narrower, corridor-like rooms that led to a coal face where each miner and his “buddy” worked in their own “room.” The colliers left large pillars of coal standing as they cut the face forward and sideways through “breakthroughs” that led to parallel rooms. This was the “room and pillar” method of mining common in the Appalachian bituminous coalfields.

When a miner and his helper approached the entry to their room, danger lurked in almost every move they made. First, the men had to push an empty coal car up wooden rails that they had installed on their own time. “A man sometimes had to get down on his hands and knees, with his left shoulder, well padded, against the car, bracing himself with his toes against the ties and the dirt of the floor,” wrote a former miner, while his partner controlled the brakes “to keep the car from rolling back on the pusher if he slipped or grew tired.” Back injuries, broken legs, and severed feet and fingers were common.

Next came preparations for extracting the coal. At the far end of the room, the miner lay down on his side and cut under the bottom of the coal face with his pick, inching his way into the cut and hoping the coal was hard enough not to collapse on him. After undercutting the face, the collier turned the crank on a five-and-a-half-foot-long breast auger and pushed with all his weight to bore a hole high on the face. Using a thin iron needle about the thickness of a pencil, he shoved a cartridge of black powder into the hole and pushed a little clay into the hole with a damper; then he carefully withdrew the needle and inserted a wick of waxed paper, a squib, that would burn down to the black powder. When he lit the fuse, the lead miner hollered, “Fire in the hole,” and scuttled out of the room with his buddy.

The correct use of explosives depended on the miner’s skill and knowledge of how to drill, how much powder to use, and how to damp a charge properly. Besides know-how, the miners depended upon instinct and luck. In some cases, when a shot backfired out of the hole, it ignited coal dust or gas in the miner’s room and sent fire bursting into the main tunnel, where it could burn or suffocate the mules and their drivers passing through. This risk increased enormously when inexperienced miners failed to undercut the coal before blasting and took the risk of “shooting on the solid.”

A good blast could bring down a ton or more of coal from the fractured face. When the smoke cleared, the collier and his buddy would swing their picks to break up large clumps of coal and shovel the smaller lumps into a mine car; it was back-aching work made more painful by the narrowness of the room. Kanawha County coal seams were relatively thick, so men could often stand or just bend slightly, but some coal cutters had to work bent over all day in “low coal.” After sorting out the slate fragments and loading the car, the miner attached his brass check to the side of the car and pushed it out into the main tunnel, where mules or a small locomotive pulled the load out of the mine to the weigh station and then to the tipple, where the coal would be prepared and funneled into railroad cars.

A strong, skilled coal loader might fill five or more cars in a day. In West Virginia’s colliers, miners were paid 49 cents per ton of clean coal, compared with 76 cents in the unionized mines of Ohio. Under these terms, a hard worker could earn $2.00 for ten to twelve hours of labor, if the work was steady. But on some weeks, a miner might work only two or three days because the railroad failed to supply enough coal cars, or because the mine needed repairs. Even in a good week, there was unpaid work to perform: propping up newly opened rooms with wooden posts, laying track to his room, and lowering the floor of the main tunnel so loaded coal cars could pass through. The miners called this unpaid labor “company work.”

The workday ended at 5:30 in the evening when the sunlight had already faded over the mountains. Then the men and boys would gather their tools and trudge down the mountainside to their little cabins to wash off the coal dust that smudged their faces, necks, arms, and hands, and to sit down for an evening meal.

This was the world Frank Keeney entered as a boy. After a temporary escape to attend grammar school, it was the world he reentered in 1900 as an eighteen-year-old man willing and able to load coal for a miner’s pay. As a novice, Keeney learned the collier’s trade from older craftsmen—the skills of cutting the face, setting the charges, and loading the coal without wrenching his back or crippling himself. He also absorbed the habits and traditions that gave pick and shovel miners a remarkable degree of freedom. Hourly employees were bound to the ten-hour day, but the coal loaders, or “tonnage men,” often worked fewer hours and sometimes exercised the right to leave the mine without permission. The carpenters, mechanics, mule skinners, and other mine employees, who enjoyed no such latitude, were known by pit-face miners as “company men.” By contrast, the pit-face miners saw themselves as autonomous workmen who labored for themselves as well as for the company.

Mine foremen attempted various forms of industrial discipline to maximize productivity, but in the early 1900s, coal miners experienced little of the supervision foremen and factory managers imposed on workers; in fact, veteran colliers often became surly when a mine foreman came by their place on his little scooter to check on them. Self-respecting craftsmen were even known to stop working when a foreman came by to inspect their room. In some cases, when word came around that a miner had been scolded or punished by a boss, workers would gather on a pile of slate to talk about the incident, and the bolder ones with a “manly bearing toward the boss” would speak up for their fellow worker. Few words meant more to mine workers than “manliness,” a quality that connoted “dignity, respectability, defiant egalitarianism, and patriarchal male supremacy,” in the words of historian David Montgomery. These were the underground attitudes Frank Keeney absorbed as he entered manhood as a coal miner.

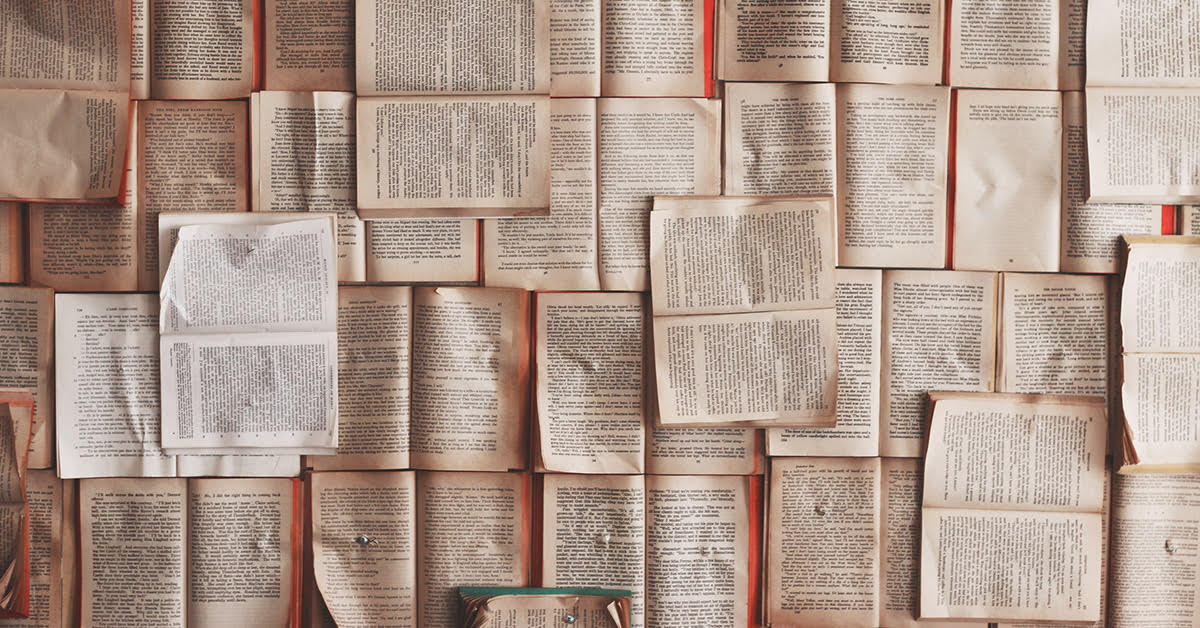

West Virginia miners begin a ten-hour shift with a boy starting his career as a “picker.”

West Virginia miners begin a ten-hour shift with a boy starting his career as a “picker.”

The mine operators assumed that if they paid a worker according to the number of tons he loaded, they would foster a competitive climate underground; and in a sense, the tonnage system worked this way. The strongest, most efficient men earned the most money at the end of the day. Frank Keeney wanted to be a first-class tonnage man because he needed to support his widowed mother and two sisters, along with his new wife, a fair teenager named Bessie Meadows, an Eskdale girl who wanted to become a schoolteacher.

A miner’s compulsion to load as much coal as possible was tempered by experience, however. Veteran colliers knew competitive individualism bred greed, hostility, thievery, and a disregard for mine safety. Stealing another man’s coal was considered a “terrible crime.” A thief could commit this offense easily, simply by removing one miner’s brass check from his coal car and replacing it with his own; but the miners often detected this kind of trickery and banded together to demand the thief’s termination. Taking a mine car out of turn constituted another grave offense. Every workingman was supposed to have his turn when it came to getting an empty coal car, because each collier deserved an equal opportunity to get his load to the weigh station. Coal loaders at the face depended on mule drivers and motor men to honor the old tradition of a “square turn”—“a custom through which colliers sought to control output and equalize earning opportunities by ensuring that each miner would receive the same number of cars during a workday,” in the words of a mine industry historian.

Aboveground, many miners suffered at the hands of the company men who short-weighed tonnage a man had loaded or docked his pay because slate was found mixed in with the coal. The need to correct these abuses led the UMWA to demand the employment of a “check-weigh man” whom the miners could trust. A standard tune in miners’ lore began with lyric, “You’ve been docked and docked again, boys / You’ve been loading two for one,” and asked what the miner had to show for working so hard. “Nothing” was the answer, nothing but the miserable life he and his family endured living in rented shanties hard on the railroad tracks. But to those who suffered alone in silence, the chorus offered hope and strength:

Union miners, stand together!

Heed no operator’s tale!

Keep your hand upon the dollar,

And your eye upon the scale!

Green miners like Frank Keeney also learned that surviving underground required men to depend upon each other and to honor the wisdom of the most experienced men. The craftiness and deftness of the best colliers was most evident when they performed the riskiest task of all. After workers had advanced the mine face to the end of the seam, veterans began the dangerous work of removing the massive coal pillars that stood between the rooms and helped support the mine top. “Retreat mining” required the rapid destruction of these pillars, each containing tons of valuable coal, before the mine collapsed. As the men removed one pillar after another, the wooden posts used to support the mine top would be strained as the roof started “getting heavy.” The wood would then creak and groan and then splinter as the miners heard the roof “working” above their heads and planned their retreat accordingly.

After they loaded coal from the fallen pillars, the colliers and their helpers pushed their cars out into the main entry as fast as possible before sections of the roof collapsed. After the top fell, they returned to break and load the fallen coal before another layer of the top came crashing down with a tremendous roar. “An experienced miner would often work calmly under conditions that would terrify a novice,” wrote a veteran of the bituminous mines.

Retreat mining was a risky business, but at least the miners engineered these cave-ins. Under other circumstances, mine tops fell without warning. Even the most skilled miners could not detect the presence of kettle bottoms, the petrified remains of huge ancient tree trunks that could plunge through the roofs and crush workers. During the early 1900s, roof falls in the bituminous coal mines killed an average of 886 workers every year, as compared with the 274 deaths per year caused by explosions and fires. In West Virginia, where mines were cut near the mountaintops, the overburden was looser and more prone to collapse than in the deeper shaft mines of the North.

West Virginia’s mine safety laws were the weakest in the nation. One statute required operators to print maps of their mines, but it excluded any provisions for enforcing this requirement. Another statute required employers to hire pit bosses to examine every working place in the mine, but only “as often as practicable.” A third rule required the managers to water the coal dust, but only when they detected a dangerous level of gas. The failure of a mine boss to dampen the coal dust was the reason the Red Ash mine blew up in 1905, killing thirteen men and boys on Fire Creek. Red Ash mine was also the location of a disaster in 1900, which killed forty-six miners. This earlier catastrophe outraged Mother Jones, who spoke of it often on her organizing campaign that year, and it had triggered public pressure to improve the state’s mine safety laws. The legislature rejected all proposals for reform, however. The lawmakers apparently agreed with West Virginia’s Republican governor, G. W. Atkinson, who said in 1901: “It is but the natural course of mining events that men should be injured and killed by accidents.”

Regardless of what their state government might or might not do to protect them, the miners of West Virginia had to rely on themselves and their buddies, rather than on company fire bosses and state mine inspectors, whose numbers were few and whose visits were infrequent. Coal diggers gave up some of their hard-earned pay to aid fellow miners when they were sick or injured, and when a mine exploded, they risked their lives to rescue the survivors trapped inside. If a man died in a mine, they quit work to honor him and to take up a collection for his surviving wife and children. On one hand, the miners’ discipline and death-defying courage made them ideal industrial soldiers; on the other hand, the qualities the men forged in underground combat with the elements—bravery, fraternal fealty, and group solidarity—hardened them for aboveground combat with their employers.

From THE DEVIL HERE IN THESE HILLS (Atlantic Monthly Press), now out in paperback.

James Green

James Green is a historian and the author of six books on American labor and radical movements, including Death in the Haymarket: A Story of Chicago, the First Labor Movement and the Bombing that Divided Gilded Age America. Green received his PhD in history from Yale University and is a professor of history at the University of Massachusetts Boston. He lives in Somerville, Massachusetts.